For any small business, inventory management is the art and science of ordering, storing, and selling your products to make the most profit while keeping costs down. It’s a constant balancing act. Order too little, and you risk frustrating customers with stockouts. Order too much, and you're stuck with cash tied up in products gathering dust.

When you nail it, though, what was once a major operational headache becomes a powerful engine for growth.

Why Smart Inventory Management Is a Game Changer

Wrestling with inventory can feel like a losing battle. You’re trying to predict demand, avoid tying up precious cash in overstock, and prevent that dreaded "out of stock" message that sends customers straight to your competitors. It's easy to just accept this chaos as a cost of doing business, but the reality is that poor inventory control has a massive impact.

It's a surprisingly common problem. A staggering 43% of small businesses either don't track their inventory at all or are still using outdated manual methods. Think about that. Nearly half are essentially flying blind, which leads to huge inefficiencies. These poor practices can cost businesses up to 11% of their annual revenue from entirely preventable issues like stockouts and overstocking.

Moving Beyond Damage Control

Getting your inventory in order isn't just about plugging leaks and preventing losses; it’s a strategic move that directly fuels growth.

When you have a clear, accurate picture of your stock levels, you can make purchasing decisions with confidence instead of just guessing. No more panicked, expensive rush orders or sitting on a pile of seasonal items long after their peak. This clarity has a direct and immediate impact on your financial health.

In fact, one of the biggest ways smart inventory management changes the game is by freeing up your cash flow. When your capital isn’t locked up in slow-moving products, it’s available to be invested in marketing, product development, or other areas that actually grow your business. Learning about essential cash flow management strategies really drives home how deeply intertwined these two functions are.

Key Takeaway: Effective inventory management transforms your stock from a liability that costs you money into a dynamic asset that generates revenue and provides critical business insights.

The True Cost of a Disorganized Stockroom

The consequences of messy inventory control go way beyond the numbers on a spreadsheet. There are a lot of hidden costs that can quietly cripple a small business.

Think about what really happens when your stockroom is a mess:

- Damaged Customer Trust: A stockout doesn't just lose you a single sale. It tells a customer they can't rely on you, and you might lose their loyalty for good.

- Inefficient Operations: Every minute your team spends searching for a misplaced item or doing a manual recount is a minute they aren't spending on sales or helping customers.

- Wasted Space: Every square foot of your storage area costs you money, whether it's rent or a mortgage. Filling it with unsold goods is like paying to store clutter.

- Lost Opportunities: Without accurate data, you can't spot sales trends. You could completely miss a sudden surge in demand for a product simply because you weren’t prepared. Having high-quality visuals is also a great way to see what's popular; you can get key insights from professional photo editing services for ecommerce that highlight your best-sellers.

Finding the Right Inventory Method for Your Business

Figuring out how to handle your stock isn't about finding some mythical "best" method. It’s about finding the best fit for what you actually sell. What works for a local bakery with fresh bread would be an absolute train wreck for a boutique selling high-value, handmade jewelry.

The right inventory management approach for a small business really just boils down to your products, how fast they sell, and your overall business model. The goal is to pick a framework that brings some much-needed clarity and control to your day-to-day operations. Don't get bogged down by confusing jargon—just focus on a few proven techniques and see which one clicks with your reality.

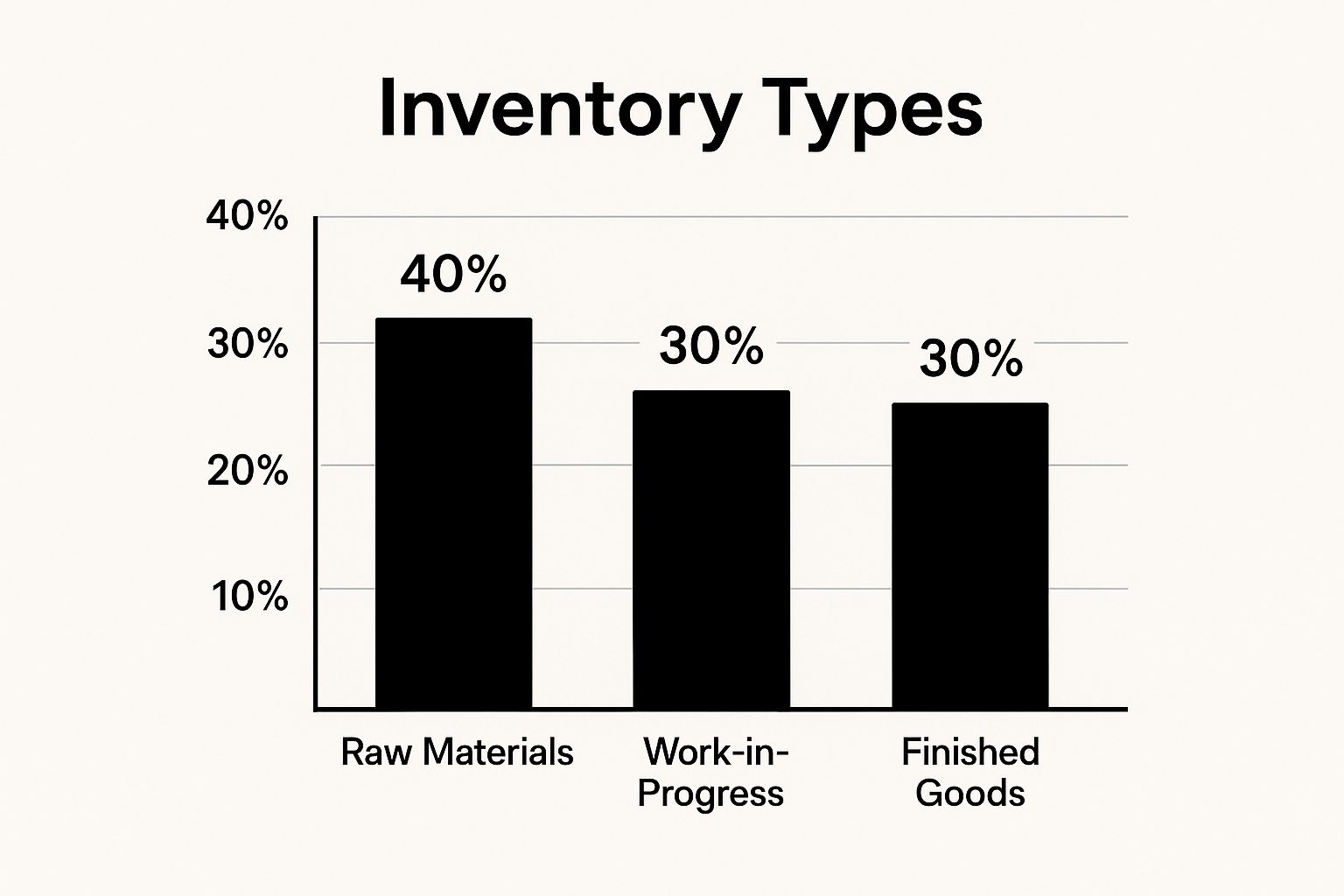

A lot of people think "inventory" just means finished products sitting on a shelf, but it’s so much more than that. It’s a whole pipeline.

As you can see, inventory is the raw materials, the works-in-progress, and the finished goods. It's the entire flow of value moving through your business.

Popular Inventory Techniques Explained

Let's walk through three of the most common and effective methods. I'll use some real-world examples to make it tangible.

-

First-In, First-Out (FIFO): This one is exactly what it sounds like and it's non-negotiable if you deal with perishable or time-sensitive goods. The first items that come into your stockroom are the first ones you sell. Think of a local coffee shop selling pastries; they use FIFO to make sure the freshest croissants are always sold first, which cuts down on spoilage and waste. This is also critical for things with expiration dates, like skincare or supplements.

-

ABC Analysis: This technique is basically the Pareto Principle (the 80/20 rule) applied to your stock. You categorize everything into three buckets based on its value. Your 'A' items are the high-value stars that make you the most money. 'B' items are your middle-of-the-road sellers. 'C' items are the low-cost, high-volume things. An online art print shop might use this to focus their energy on their best-selling, high-margin canvas prints ('A' items) while spending way less time meticulously tracking cheap packing tape ('C' items).

-

Just-in-Time (JIT): JIT is a bit more advanced. The idea is to order inventory from your suppliers only when you need it to fulfill an actual customer order. This can slash your storage costs and prevent you from getting stuck with stuff that doesn't sell. A business that makes custom-printed phone cases is a perfect candidate for this. They only order the blank cases after a customer pays for a specific design, so they never have a box of unsold iPhone 6 cases collecting dust.

Expert Tip: Don't feel like you have to go all-in on one complex system from day one. Start simple. Many small businesses do great by blending methods. You could use FIFO for all your products while running an ABC analysis once a quarter to see which items are still your top performers.

A Quick Comparison of Inventory Management Techniques

To help you see which approach might align with your business, I've put together a simple comparison table. Use this as a quick reference to see where your business model and products fit best.

| Technique | Ideal For | Main Advantage |

|---|---|---|

| FIFO | Businesses with perishable goods (food, cosmetics, supplements) | Reduces spoilage and ensures product freshness |

| ABC Analysis | Retailers with a wide variety of products (boutiques, gift shops) | Focuses resources on the most profitable items |

| JIT | Made-to-order or custom product businesses (print shops, custom furniture) | Minimizes storage costs and eliminates overstock risk |

Ultimately, the right choice gives you control and a clear picture of your most valuable assets. It's less about complex spreadsheets and more about making smarter, more profitable decisions for your business.

Choosing Your First Inventory Management Software

Making the leap from a spreadsheet to dedicated software is a huge milestone for any business. It’s that moment you decide to stop putting out inventory fires and start preventing them in the first place.

The market is flooded with options, and it’s easy to get overwhelmed. But finding the right tool really just boils down to focusing on the features that solve your specific problems as a small business. Don't get distracted by flashy dashboards; your goal is to find a system that fixes today’s chaos and can grow with you. The last thing you want is a costly, frustrating switch in a couple of years.

Must-Have Features for Small Businesses

When you start looking at software, you need to cut through the marketing fluff and focus on the core functions. These are the features that deliver immediate value and will quickly become the backbone of your operations.

-

Real-Time, Multi-Channel Syncing: This is non-negotiable if you sell in more than one place, like on your website and at a local market. When an item sells on your Shopify store, the software must instantly update the stock level available through your point-of-sale (POS) system. This one feature prevents the dreaded oversell—selling the same item twice.

-

Automated Low-Stock Alerts: Let the software do the worrying for you. A good system lets you set a minimum stock level (often called a "par level") for every product. Once your inventory hits that number, the system automatically pings you with an alert. This gives you plenty of runway to reorder before you run out.

-

Simple Sales and Inventory Reporting: The right software turns your sales data into clear, actionable insights. Look for easy-to-read reports that show you which products are flying off the shelves, which ones are collecting dust, and what your inventory turnover rate looks like. This data is absolute gold for making smarter purchasing decisions.

A critical part of showcasing your products effectively online involves high-quality visuals. For a streamlined way to manage and optimize your images, explore how an intuitive product photo dashboard can simplify your workflow.

Thinking Beyond the Monthly Fee

Pricing for inventory management software can be a bit tricky. That low monthly fee might look great on the surface, but it's vital to understand the total cost of ownership to avoid any nasty surprises down the road.

First, get crystal clear on the pricing tiers. Many platforms bill you based on the number of users, SKUs (your unique products), sales channels, or monthly orders. A plan that seems like a bargain today could get expensive fast once your business starts to grow.

Ask them direct questions. What happens if I add another sales channel? What if I go over 1,000 orders in a month?

You also need to sniff out any hidden costs. Some companies charge extra for things like initial setup help, migrating data from your spreadsheets, or even just getting access to customer support. A slightly more expensive plan that includes comprehensive support might actually be a much better value than a cheaper one that leaves you stranded when you need help.

Ultimately, choosing the right software is an investment in your business's future. The goal is to find a partner that simplifies your day-to-day, saves you time, and gives you the data you need to grow with confidence.

A Practical Guide to Implementing Your New System

You’ve done the hard part and picked your software—now for the moment of truth. A smooth rollout is what separates a game-changing tool from a frustrating, expensive headache. This isn't just about plugging in new tech; it's about fundamentally changing how your business operates without bringing everything to a screeching halt.

A well-planned implementation avoids the data errors and team frustration that can poison a new system right from the start. The real goal here is to get up and running efficiently, with clean data and a team that’s actually excited to use the new tool.

Preparing for a Clean Data Import

I've seen it a hundred times: the single biggest mistake you can make is dumping messy, inaccurate data into a brand-new system. It’s the classic "garbage in, garbage out" problem. Before you even think about uploading a spreadsheet, you have to establish a single source of truth for your inventory.

This all starts with a full, wall-to-wall physical stock count. Yes, it’s tedious, but it is absolutely non-negotiable. You need an accurate baseline of every single item you have on hand, period. Once you have that solid number, you can get your product data ready for a clean import by making sure everything is formatted consistently.

Your import file should nail down the essentials for each product:

- SKU (Stock Keeping Unit): Your unique code for every item variation.

- Product Name: A clear, consistent description everyone understands.

- Supplier Information: Who you get the product from.

- Cost Price: What you actually pay for the item.

- Retail Price: What your customer pays for it.

Key Insight: Taking the time to clean up and standardize your data before you import it will save you dozens, if not hundreds, of hours of troubleshooting later. A clean start is the most critical part of this entire process.

Configuring Your System and Training Your Team

With clean data in hand, you can move on to the fun part: setting up the software to work for your business and getting your team on board. This is where the system starts to feel real.

A great first step is to configure your initial automated reorder points, sometimes called par levels. Pick your top-selling items and set a minimum quantity that triggers an automatic alert to restock. This one simple action immediately takes the guesswork out of managing your most important products. For a more detailed walkthrough, this is an excellent guide on how to create an inventory system.

Next, you have to focus on the human element. The best software in the world is useless if your team doesn't know how to use it—or worse, doesn't want to.

Schedule dedicated training sessions. But don't just show them how to click the buttons; explain why this new way is better. Frame it as a tool that will make their jobs easier. No more hunting for lost stock or spending hours on manual counts.

Getting this buy-in from your team is everything. Once they see the benefits for themselves, they'll become the biggest champions of keeping the data accurate. And for e-commerce businesses, remember that your product visuals need to be just as organized as your stock levels. Looking into the pricing for AI photo editing can help you budget for that professional online look. A slick inventory system paired with amazing product photos is a powerful recipe for growth.

Mastering Ongoing Inventory Control and Optimization

Getting your inventory management system up and running is a huge milestone, but it's not the finish line. In fact, this is where the real work begins. Now you shift from just setting things up to actively optimizing your stock. This is the moment your new system transforms from a simple tracking tool into a strategic asset that actually helps you make smarter business decisions.

The habits you build right now are what will keep your stock levels accurate and your business profitable for years to come. Without consistent control, even the fanciest software will slowly fill with bad data, landing you right back where you started.

Adopt Cycle Counting for Consistent Accuracy

One of the most powerful habits you can adopt is cycle counting. Forget the stressful, all-hands-on-deck annual inventory count that shuts down your whole operation. Cycle counting is all about counting small, specific sections of your inventory on a regular schedule. This approach keeps your data clean all year round without ever having to close your doors.

Think about it like this. If you run a small boutique, you could:

- Count your top 20% best-selling dresses every single Monday.

- Tally up mid-range accessories every other Friday.

- Check your slow-moving, seasonal items just once a quarter.

This method helps you catch discrepancies—like a mis-shipment from a vendor or even potential theft—almost as soon as they happen. It’s a game-changer, especially when you consider that retail inventory accuracy in the US hovers around a dismal 63%. Those mistakes contribute to a staggering $1.6 trillion in annual losses for businesses worldwide due to things like stockouts and overstock.

By making small, regular counts part of your weekly routine, you maintain a perpetually accurate inventory record. That accuracy is the foundation for every other smart business decision you'll make.

Leverage Sales Data for Smarter Forecasting

Your new inventory software is an absolute goldmine of sales data. This information is your ticket to moving beyond just reacting to what you need and into proactively forecasting what your customers will want. It’s time to dig into your reports to spot trends and make much smarter buying decisions.

Start asking the right questions:

- Which products fly off the shelves every summer?

- What items consistently sell out before your next shipment arrives?

- Are there products that have barely moved in the last six months?

This kind of data-driven insight allows you to anticipate customer needs, making sure you have the right products on hand at the right time. This has a massive, positive impact on your cash flow. A huge part of inventory optimization is actively shortening your cash conversion cycle by turning your stock into sales much faster.

This information also gives you a ton of leverage with your suppliers. When you can give a vendor a reliable forecast of what you'll need for the next six months, you’re no longer just another small account. You become a predictable, valuable partner. That can open the door to negotiating better pricing, more favorable payment terms, or even getting priority access to new products. Your inventory data just became your best negotiation tool.

Got Inventory Questions? We’ve Got Answers.

Jumping into a new inventory system is a huge step, and it's totally normal to have a million questions pop up. It's a core part of your business, after all. Let’s walk through some of the most common questions I hear from fellow business owners to clear things up and get you moving in the right direction.

How Often Should I Really Be Counting My Inventory?

That massive, once-a-year physical count is non-negotiable for taxes, but if that’s the only time you’re counting, you’re flying blind for 364 days. So much can get lost, misplaced, or broken in that time. The smarter play here is cycle counting.

Cycle counting just means you count small, specific sections of your stock on a regular, rotating basis. It’s way less of a headache than shutting down the whole operation for a weekend.

For instance, if you run a small online shop, your cycle could look like this:

- Count your top 20% of best-sellers (your "A" items) every two weeks. These are your money-makers, so you need to know exactly where they stand.

- Tally up your mid-range sellers once a month.

- Check on your slow-moving items just once a quarter.

Making this a habit means you catch problems—like receiving mistakes, stuff getting put in the wrong bin, or even theft—almost as they happen. It keeps your data clean, which is the whole point of having a system in the first place.

My Stockroom Is a Disaster. Where Do I Even Begin?

If you feel like you're drowning in stockroom chaos, you're not alone. The very first thing you have to do, no exceptions, is a complete, wall-to-wall physical count. You can't start managing your inventory until you know precisely what you have.

Try to schedule a day where you can pause all incoming and outgoing shipments. This gives you a clean, frozen snapshot of every single item. I know, it's a grind. But it’s the only way to establish a single source of truth.

You can't build a solid system on a foundation of bad data. Once you have that perfectly accurate baseline count, you can plug it into your new software with confidence. That clean start will save you countless headaches down the road.

Can I Just Use a Spreadsheet to Manage Everything?

Look, if you're just starting out with a handful of products, a spreadsheet can work as a temporary fix. But it's a manual process, prone to human error, and it hits a wall the second you start to grow.

A spreadsheet can't tell you what your real-time stock levels are if you're selling from an online store and a pop-up market at the same time. It's not going to ping you with an urgent alert when your best-seller is about to run out during a flash sale. The hours you'll waste on manual updates and the sales you'll lose from stockouts will quickly add up to more than the cost of a basic inventory software subscription.

How Do I Figure Out My Inventory Turnover Ratio?

This is a really important metric. It tells you how quickly you’re selling through your inventory, which is a key indicator of your business's health. Generally, a higher number is better.

The formula itself is pretty simple: Cost of Goods Sold (COGS) ÷ Average Inventory.

You can pull your COGS right from your income statement. To find your average inventory, just take your beginning and ending inventory values for a period (say, a year), add them together, and divide by two. Once you have your number, compare it to others in your industry. That context is what tells you if you're truly performing well.

Ready to make your products look as professional as your new inventory system? ProdShot uses AI to turn simple phone photos into stunning, high-quality product images in seconds. Stop wrestling with complicated editing software and start creating visuals that sell. Try ProdShot for free and see the difference it makes.